3min read

The first battery driven electromechanical calibers such as the LIP R27, and the Ebauches SA (ESA) L4750/51 had one major flaw. One specific electric contact was oxidising and sometimes sparking when in use, which would wreck the movement and increased the energy draw from the battery. To avoid this problem André Beyner’s team at ESA thought of integrating a germanium transistor (1).

ESA already had a pilot facility to fabricate germanium transistors starting from 1958, using a license from Phillips (NL), who licensed the procedure from Western Electric / Bell Labs (USA) already from 1952 (1).

The work on the new electromechanical caliber which should replace the L4750/51, started in 1960, with a patent already submitted in 1962, by the two ESA engineers André Hug and René Meister (1).

–

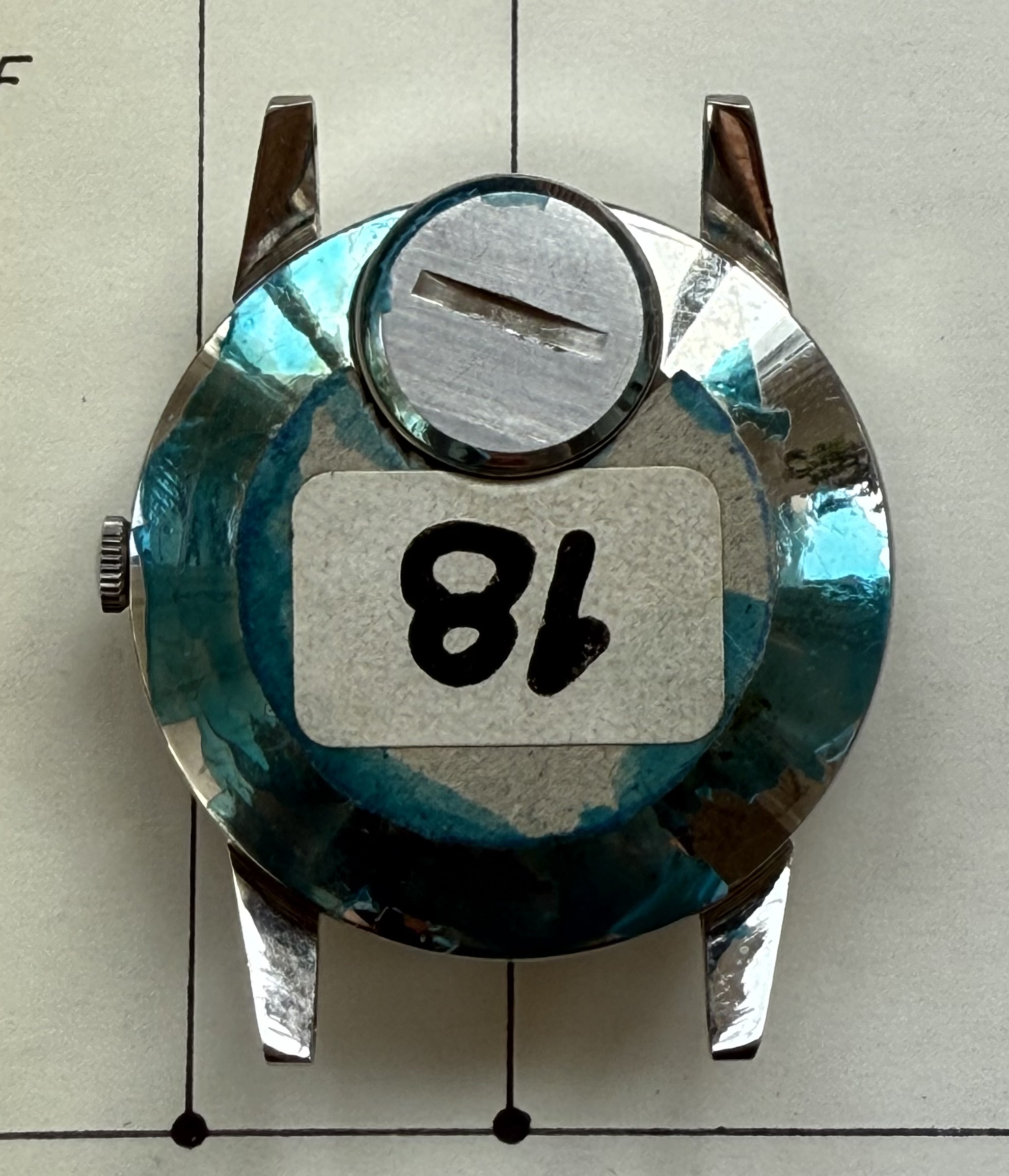

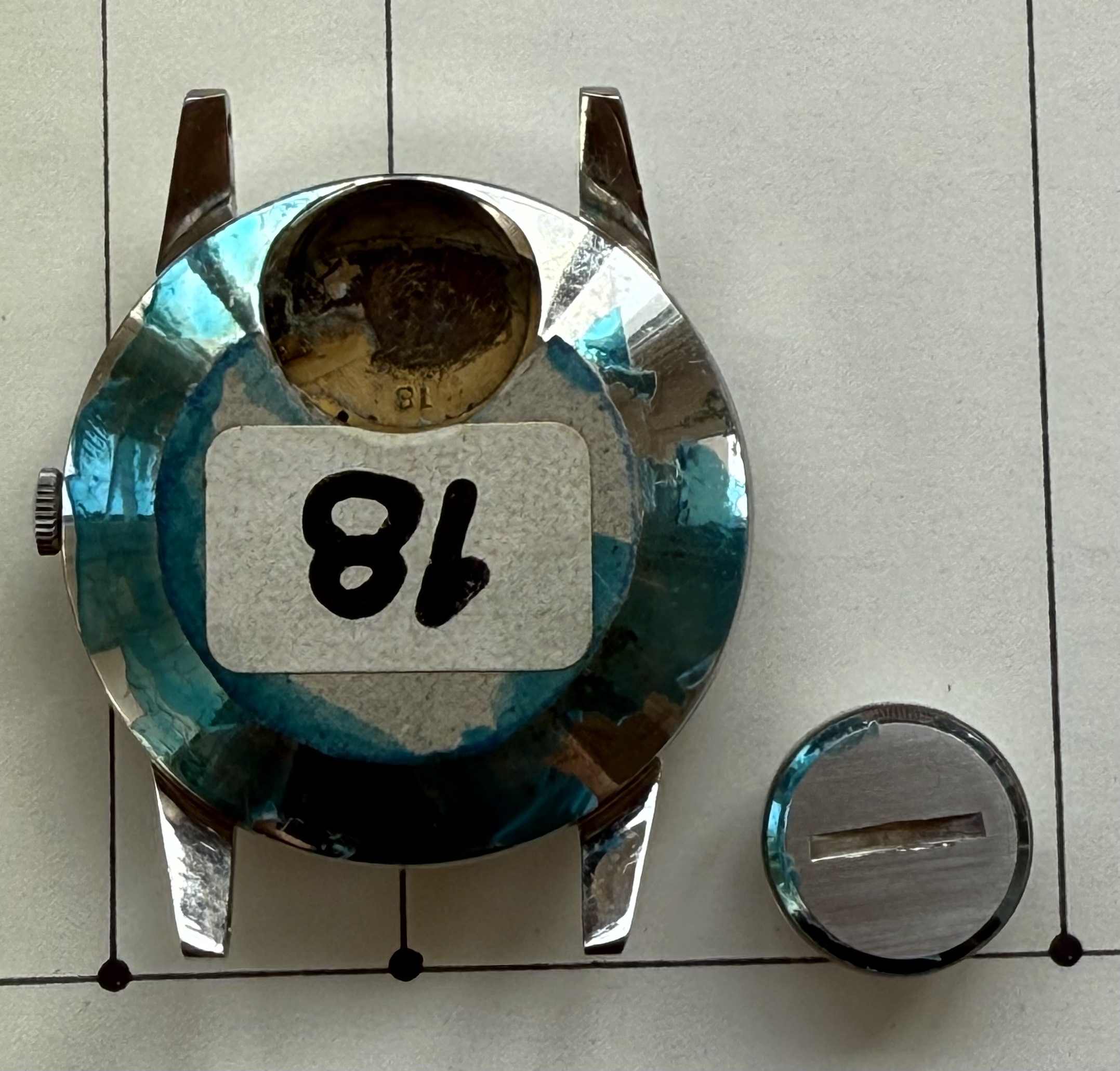

Ebauches SA, Dynotron Prototype #18, 1962

Category: proof of principle

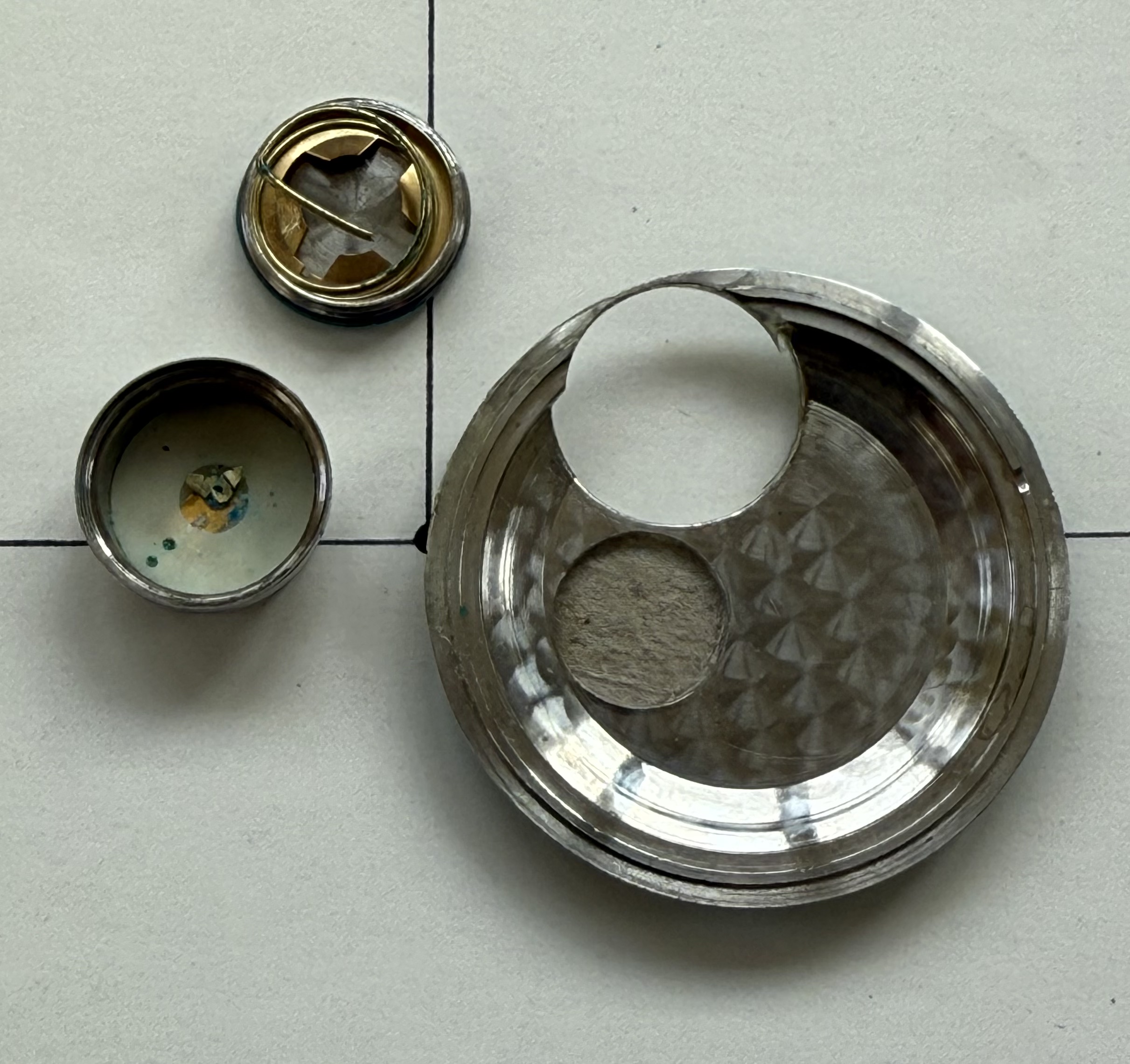

Description: Round, nickel plated, brass cased prototype with polished surfaces (EPSA, E. Piquerez SA). Stainless steel snap case back with no engraving, but covered with a felt pad and all is covered by blue wax. Separate cylindrical battery case with screwed down cover. Press fitted, brass movement holder, movement press fitted into the brass holder. Silver dial with raised, gilt 5min baton indexes and ESA logo at ’12’, black printed ‘Swiss’ at ‘6’. Silver hands and original acrylic crystal. Gilt, base metal crown.

Dimensions: 35mm (without crown), lug – lug: 44mm, lug width: 19mm

Movement: ESA cal.: 9150 Dynotron prototype #18

Additional info: These piece represents the earliest transistorised Swiss movement made and the earliest working prototype version for the ‘Dyontron 9150’ caliber, which will be a great success and distributed to over 30 watch manufacturers also abroad (4). There will be numerous variations of this movement and these will be sold until 1977.

The movement shows a double balance made of plastic with metallic elements. The two levels of the balance pass by a fixed coil. The brass parts of the movement are raw with no gilding. Analog electric elements (diodes and transistor) are welded and connected onto a brown wafer, which is marked ’18’ as the brass main plate. There is also a marking ‘S1’ which meaning has not been identified yet.

However, it is known, that LIP worked on the problem of sparking contact, and also worked on a transistorised version of their R27 movement after the launch of the model in 1958 (see picture above, picture credits (3)). This version was never marketed, also because the prerequisites for electric watch calibers were soon to be greatly influenced by the release of the Bulova Accutron in late 1960.

The inconvenience of the watches bearing cal.: R27 was, that they were extremely expensive, to the contrary of Lip’s philosophy to produce good quality watches for all social levels. With the release of the Accutron in 1960, Lip was under pressure to simplify the R27 caliber and also to house only one battery, as the Accutron did. The alternative of developing an own version of a metallic tuning fork caliber was excluded, due to the lack of time, experience and machinery (5).

The development for a successor of the R27 caliber, which will be named R148, had to be made quite fast, and LIP took take great inspiration from the one coil caliber developments at Elgin (USA). Moreover, the development had to be accelerated as Fred Lip was about to sign a license deal with Hamilton to use their 500 caliber (2). Lip will issue their improved cal.: R148, in 1962, in the USA and 1963 in France (5).

Provenance: Ex. Hans Baumann collection

Published: Bramaz H.-R., Baumann H.; Die Elektrische Armbanduhr, Band 1, Verlag Stutz Druck AG, Wädenswil, 2013, page xx, picture x

Ref.:

- Comunication with a former Executive Vice-President of Ebauches SA, in charge of Research & Engineering.

- Personal communication with Michael – @elgindownunder

- Michael – @elgindownunder

- Bramaz H.-R., Baumann H.; Die Elektrische Armbanduhr, Band 1, Verlag Stutz Druck AG, Wädenswil, 2013

- Watchesz