13min read

Beta 21 , The Industrial Version

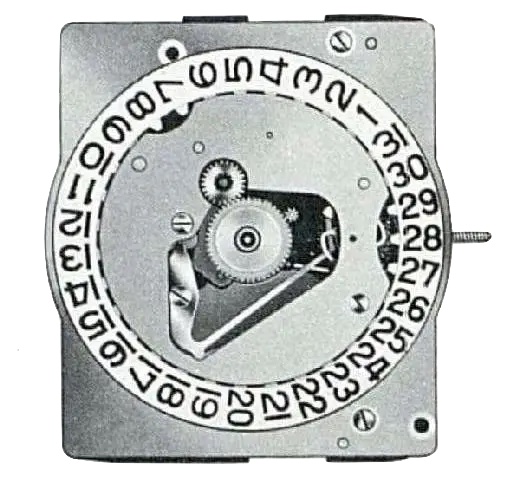

The future industrial caliber was named Beta 21, actually Beta 2.1 (two point one) as it represented the first derivate of Beta 2 (5). CEH engineers completely redesigned the Beta 2 movement to create the production model. A calendar complication was judged important for a ‘luxury quartz watch’ by some members of CEH, so it was added together with an instant date change and quick-set by pressing and rotating the crown. François Niklès designed brilliantly the mechanical parts and the over-all construction of the movement. The driver and divider circuits were also redesigned to reduce current consumption.

‘Communauté d’intérêt Beta’ – Community of Interest in Beta

The CEH was a research facility and not a production firm, moreover a not negligible part of the shareholders of CEH were organisatory groups or suppliers and not manufacturers of complete movements or watches and were mostly interested in the further advancement of scientific research and not in an imminent industrialisation. Hence, the step towards industrial production of Beta 21 would be realised by a core group within CEH named the ‘Community of interest in Beta’. The frame for this core group was already shaped during a meeting the 03.04.1968. The minutes of the meeting being known as the ‘Mottu report’, which shows the main goals of the future community (8):

- Industrial core facility would be Omega

- The establishment of a road map for industrial production of Beta 21

- Shared responsibilities between CEH and the future ‘Community of interest in Beta’

- CEH will build few prototypes followed by a ‘zero’-series of 6000 pieces made within the ‘Community of interest in Beta’

The official creation of the ‘Community of interest in Beta’ dates from the 22.05.1969, but the actual work started earlier, in order to ensure timely production. 20 of the original 32 members of CEH would be part of this community (8):

- 1 organisatory organ: FH (Federation Horlogère)

- 4 suppliers: ESA (Ebauches SA), FAR (Fabriques d’assortiments réunies), FBR (Fabriques de balanciers réunies), FSR (Fabriques de spirales réunies)

- 15 manufacturers: Bulova, Crédos SA, Complications SA (Piaget), CHP (Communauté d’Horlogerie de Precision), Elgin SA, Enicar SA, IWC, Le Coultre et Cie., Longines SA, Manufacture de montres Rolex (Bienne), Montres Rolex SA (Geneva), Omega, Patek Philippe, Rado, Zenith SA

The 20 members would be organised as follows (8):

- Manufacturer group with representatives of CEH and the community : CEH, Longines, Omega, ESA

- Technical commission with representatives of CEH and the community: CEH, Longines, Le Coultre, Omega, ESA, Bulova; coordination of the industrial production of Beta 21 would include three phases:

- supervision of caliber planning and construction at CEH (ends November 1968)

- manufacture of 10 prototypes at CEH (first prototype presented 25.07.1969)

- Support to produce an industrial ‘zero’-series of 6000 pieces

The manufacturer group as well as the technical commission supervised two sub-groups (8):

Sub-group; component manufacture:

- ESA: raw movement plates, wheel work, calendar

- Oscilloquartz (part of ESA): quartz manufacture and quartz casing

- Omega: vibrating motor

- CEH: electronic module, integrated circuit, trimmer

Sub-group; assembly facilities for the ‘zero’-series:

- ESA (Neuchâtel)

- Omega (Bienne)

- Common assembly facility (Yverdon) by the ‘Group of Four’ (Rolex, Le Coultre, Longines, Patek Philippe)

The first 10 CEH – Prototypes

During Summer 1969 the first hand assembled prototypes of the Beta 21 caliber were produced at the CEH. The components for the prototypes would be fabricated with help of newly developed apparatuses and assembled by hand as not the complete array of machines was yet available. These prototypes would be cased into nickel plated brass cases, which would feature an acrylic back. Some of these 10 prototypes (scratch numbered with Roman numerals on the rim of the case) would have the calendar mechanism mounted (versions starting with number CEH-211) and others would not (versions starting with number CEH-221). These Beta 21 prototypes would reveal problems not anticipated by the earlier prototypes Beta 1 and Beta 2, such as the sensitivity of the quartz to acceleration and blows. Following newly introduced dynamic tests at CEH and at the Observatory in Neuchâtel (in parallel testing their new devices for a potential ‘new chronometer competition’ for wrist watches) the suspension of the quartz inside its case was optimised to better withstand blows, while the watch is being worn at the wrist.

After the reliability and precision testing at the Observatory in Neuchâtel (the chronometer competition was halted for wrist watches) these watches would remain with the engineers and be worn as to test their function whilst on the wrist, among other things testing the stability of the rectifications of the quartz suspension. As the acrylic back used for the precision testing at the observatory was too fragile to be worn on the wrist, specific nickel plated brass case backs were manufactured (5).

The Electronics

Raymond Guye of the ‘wafer lab’ within the semiconductor laboratory of Kurt Hübner, succeeded to concentrate all electronics on a single bipolar IC (ODC-4) and drew the layout, made of 110 components. Guye succeeded where Faselec had failed, namely in mass producing the integrated circuitry for the Beta 21. Although primitive by today’s standards, it was a feat of manual layout and resulted in a a chip just 2 mm on a side. As mentioned in the explanations above, the movement was a derivate of Beta 2 and consisted further of the 8192 Hz oscillator, a five stage binary divider chain and the vibrating motor at 256 Hz. It is not to forget, that this ODC-4 IC was the first monolithic, bipolar IC in Europe (1, 6, 13, 16).

Beta 21 was supposed to be launched in late 1969, but severe production problems, especially concerning the troubleshooting, the manufacture and casing of the quartz and related components, had delayed manufacture of the prototypes by 3 months (8).

Production of the Zero – Series

Finally the timeline for the production of the 6000 pieces belonging to the ‘zero’-series was as follows (8):

- by 10.04.1970: 160 pieces

- by 31.12.1970: 296 pieces

- by 09.06.1971: 1558 pieces

- by 31.12.1971: 3200 pieces

- by 31.06.1972: 5980 pieces total

- 20 pieces would be lost due to destruction tests

The distribution of the 5980 Beta 21 calibers was done in proportion of contribution to the manufacture and distributed within the sub-groups ‘assembly for the ‘zero’-series’ (8):

- ‘Group of Four’; produced 1580 pieces, distributed to: Longines: 200; Rolex: 320; Patek Philippe: 640; Le Coultre: 130; Zenith: 250; FH: 30; CEH: 10

- Omega; produced 2487 pieces, distributed to: Omega: 1850; IWC: 587; FAR: 30; FBR: 5; FSR: 5; CEH: 10

- ESA; produced 1913 pieces, distributed to: Ebauches SA: 210; Complication SA: 370; CHP: 320; Elgin: 103; Enicar: 100; Crédos: 100; Rado: 200; Bulova: 500; CEH: 10

Presentation of Beta 21 at the Basle Fair 1970

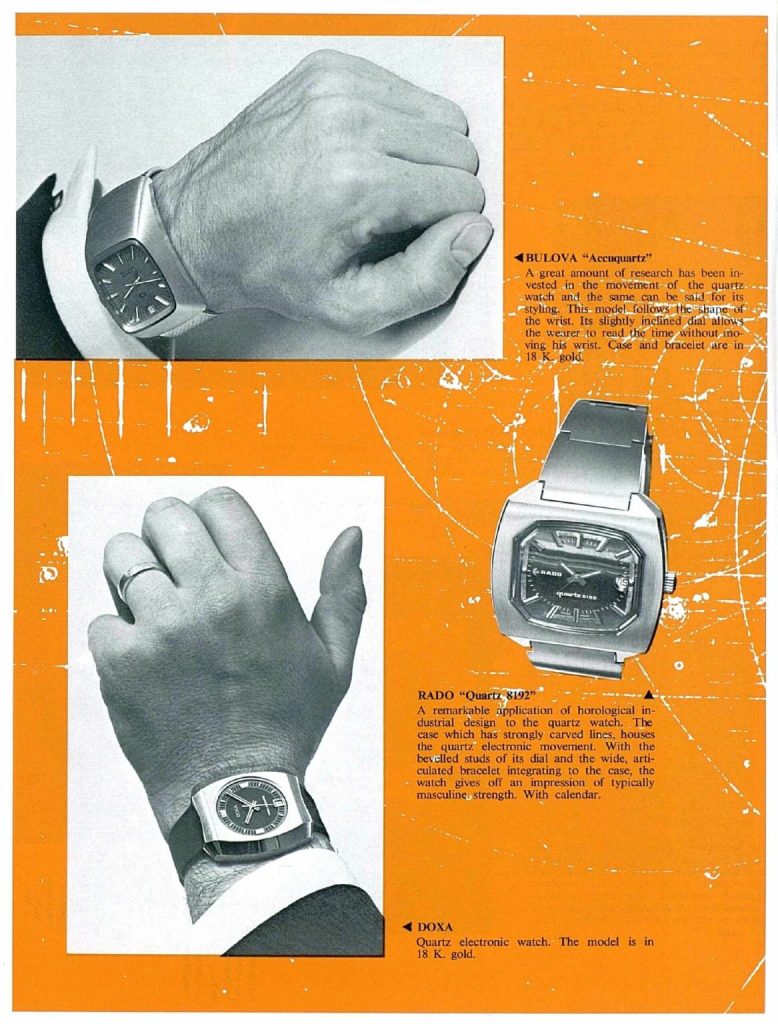

The presentation of the watches driven by Beta 21 could be held as planned at the Basle fair the 10.04.1970, but only 160 of the planned 200 watches could be shown. The Basel Fair opened with some, but not all, CEH manufacturers showing watches driven by the Beta 21 movement (2):

Bulova ‘Accuquartz’, Enicar ‘Quartz-O-D’, IWC ‘International’, Longines ‘Quartz-Chron’, Patek Philippe ‘Cercle d’Or’, Piaget ‘Ref.: 14101’, Rado ‘Quartz 8192’, Rolex ‘Ref.: 5100, Texano‘ and Omega ‘Electroquartz’

Not all members who bought a share of the 5980 Beta 21 movements would use all movements of their share, the reason being, that some companies, such as Longines, were secretly working on their own quartz movements (Longines ‘Ultra-Quartz‘) and the evolution of quartz movements in general was advancing fast. By mid 1972, when the production of the ‘zero – series’ Beta 21 movements was terminated, other smaller and better performing quartz movements were available. So some companies turned away from Beta 21 to concentrate on more modern versions. Others, such as Omega, who had invested more into the development and production of Beta 21, would buy Beta 21 movements of other companies to increase their watch production. Following latter thought it becomes clear, that the numbers for the distributed Beta 21 movements mentioned above, do not correspond exactly to the numbers of watches built and sold by the respective companies. All Beta 21 of the ‘zero’-series for all members of CEH were numbered 0000xxxx, starting with 00001001, with some companies replacing the zero-series numbering or adding their own numbering on the movement’s ‘ID – plate’ or on the case (5).

Industrial Flop

Because it was a large movement and 6.2 mm thick, the initial watches driven by the Beta 21 movement were quite unusual in design. Most featured thick rectangular cases, with quite a few being angled so the dial faced the wearer. Thanks to the rectangular shape of the movement, it was difficult to package a Beta 21 movement in a round case. IWC’s round Basel Fair design would be dropped in favour of a rectangular (‘International‘) or hexagonal (‘Da Vinci‘) case soon after. Patek Philippe’s model featured a unique case with a TV screen shaped dial, while the Rolex ‘Ref.: 5100, Texano‘ had a more traditional look apart from the lugs (2).

Beta 21 turned out to be a commercial flop. All units from the ‘zero – series’ were sold, then step by step the line with the vibrating motor was discontinued. To solve an intermediate power problem (autonomy) by pushing the vibrating motor version Beta 2 turned out to be a severe strategic error with a number of consequences. Indeed, the power problem of Beta 1 was not a systems problem but a semiconductor problem. Using Complementary Metal Oxide Semiconductors (CMOS) circuit technology instead of BIPolars (BIP) would have saved exceeding amounts of energy by orders of magnitude. CMOS was invented in 1963 and was applied later on throughout the watch industry. The CEH started early on MOS, however produced stable CMOS with silicon gate technology at a voltage level of 1.35 V only after 1970. Instead of pushing research after the splendid success at the observatory, CEH engaged excessively in technology transfer and manufacturing, losing lead time and research competence. – Not enough of all that, with their Astron 35SC the Japanese Seiko proved feasibility of an industrial watch with a stepping motor and battery lifetime of over one year (1)

Beta 21 Aftermath

So in all, almost 6,000 Beta 21 movements were produced through 1972. Later the design was modified with a thinner battery and revised trimmers and quartz modules, otherwise externally resembling Beta 21. As many as 16000 examples of the 2nd – generation version were produced (8). This movement is often called ‘Beta 22’ and Omega handled the construction of these later movements, branding them cal.: 1301 and 1302 (with no seconds or date (10)), (2), as opposed to the Beta 21 movement, which was branded cal.: 1300 by Omega (the 1300 caliber number will be re-attributed to another quartz movement later). More advanced service modules were developed by ESA /ETA through the early 1980ies (11).

The Beta 21 design was showing its age. Most companies had settled on a dead beat stepper motor design, as pioneered by the Beta 1 and Seiko Astron and famously adopted by Girard-Perregaux with their 32 KHz Cal. GP350. Girard-Perregaux and Seiko also lead the way in leveraging American semiconductor expertise, partnering with Motorola and Intersil respectively, for advanced integrated circuits. This dramatically reduced power consumption and allowed the use of faster oscillating crystals. Where the Beta 21 operated at 8192 Hz, most quartz watches since the mid-1970s have used a crystal vibrating at 32 KHz (2).

Beta 3 and Beta 4

The CEH did in fact develop ‘Beta 3’ and ‘Beta 4’ movements in later years. Beta 3, who’s first prototype was already built by December 1970 (8), was the first version to use a CMOS integrated circuit. This reduced power consumption of the frequency dividers by a factor of 20, opening the door to a higher-frequency crystal. Beta 3 also eliminated the quartz oscillator trimmer, simply ‘throwing away’ pulses instead. This required on-board memory to tune it to the crystal, which was accomplished at first with a number of small switches. Although an important development, Beta 3 was not directly put into production (2).

Beta 4, who’s first prototype was presented in November 1972 (8), was a major advancement, using a 524 KHz quartz resonator and more-advanced digital tuning system based on the Beta 3. Put into production by Piaget (Complication SA) in their cal.: 7P (1976) and cal.: 8P (1981) (10), it used volatile RAM to store the tuning information. This was adjusted using a special external timing station, which sent digital pulses to the RAM using magnetic coupling, similar to how Qi wirelesss charging works today (2).

Swiss Advances in Microelectronics

Despite the relative commercial flop of Beta 21, the dynamics initiated by the research of the CEH, pioneered by less than 10 specialist engineers in the early 1960s, plus the research efforts of Longines for their ‘Ultra-Quartz’ and Omega for their ‘Megaquartz’ high frequency system, fuelled the interest in microelectronics and highly contributed for both Swiss federal engineering schools, EPFL in Lausanne and the ETHZ in Zurich, now counting amongst the worldwide leaders in the field.

Moreover the research in microelectronics in these two universities, the CSEM, which originated from the CEH, and numerous small private companies and start-up’s have largely contributed to the fact, that microelectronic components and its derivates (generic electronic devices, precision devices, medical devices, measuring devices etc.) represent currently the second important Swiss export goods.

Ref.:

- Quartzwristwatch, Courtesy of Dr. Armin H. Frei Heritage Estate

- Grail Watch

- Watch Wiki

- ETA

- Personal communication with former engineers at CEH, working on the development of the Beta 1, Beta 2 and Beta 21 prototypes, as well as Beta 21 industrial production

- Laptrinhx

- Eperiodica

- Forrer M., LeCoultre R., Beyner A., Oguey H.; L’aventure de la montre à quartz, Centredoc, 2002

- Observatoire Cantonal de Neuchâtel, Rapport annuel du Directeur sur l’exercice, 1967

- Trueb L. F., Ramm G., Wenzig P.; Die Elektrifizierung der Armbanduhr; Ebner Verlag, 2011

- Crazywatches

- Piguet Ch.; Integrated Circuit Design Power and Timing Modeling, Optimization and Simulation 12th International Workshop, PATMOS 2002 Seville, Spain, September 11-13, 2002, B. Hochet, A. J. Acosta, M. J. Bellido (Eds.), Springer

- Personal communication with a former Executive Vice-President of Ebauches SA, in charge of Research & Engineering

- Vittoz E. A.; The Electronic Watch and Low-Power circuits; IEEE Solid-State Circuits Newsletter, February 2008

- Roger Wellinger Archive

- Privately written notes by Armin Frei and Rolf Lochinger

- CEH archives at the MIH